Newsletter July 2023

Our Customers, their aircraft…

Pierre, Max, MCR travelers…

After seeing Chabbert’s report, they went for a test flight on the MCR-4S and literally fell in love with the machine. Naturally, they didn’t hesitate: an MCR-4S kit was bought, quickly assembled and, in August 2009, its 100hp Rotax ULS started up for the first time. Registered F-PKAF, their MCR-4S is equipped with Dynon D-180 and Garmin 695. In terms of safety, in addition to an airframe parachute, an anti-collision system is installed, as there’s a lot of gliders around their Swiss airfield.

Today, the F-PKAF has logged 1,250 flying hours and, with its 200-liter long-range fuel tanks and 10-hour range at 115 kt, has criss-crossed Europe with Pierre and Max at the controls: Spain, Portugal, Germany, the English Isles of Scilly, the Czech Republic, Poland, around the Baltic Sea, Finland, Sweden, Denmark and France, which they have crossed from north to south, east to west, including memorable flights around the Mont-Blanc and to Corsica.

Africa, too, is one of their favorite destinations. They have twice taken part in the Raid Latécoère in 2015 and 2017, and in 2018 flew to Ouagadougou with Air Solidarité.

In Africa, moreover, when the air temperature reached 30°C, the Rotax tended to overheat, as the F-PKAF’s three-blade MT-Propeller didn’t ventilate sufficiently in flight. But Pierre and Max came up with a solution: they installed an E-Props with adjustable pitch and – here’s a tip for our newsletter readers – they discovered that from 3,000 rpm, the oil temperature stabilized, even in very hot weather.

Finally, it’s worth pointing out that despite being 14 years old, the MCR-4S F-PKAF is like new! Let’s not forget that Pierre Schlaffy and Max Bury are Swiss, and that Swiss precision and rigor are no legend! In fact, they spend as much time and take as much pleasure maintaining their machine as they do flying it. We know it perfectly, down to the smallest bolt, and we love tinkering with it to make sure it’s as reliable as the day it was built, explains Pierre.

n the subject of safety, Pierre and Max have decided to install the new flaps system, created by SE AVIATION AIRCRAFT. They will soon be entrusting us with their aircraft. What’s more, our new Premium cabin could soon be on the agenda too, because when you travel as much as these two men do, the comfort of ergonomic seating is essential!

Pierre speaks about his MCR…

We feel that our MCR-4S is unique, because as far as we’re concerned, it has no rivals. Its range is incredible, even greater than the pilot’s, because after 5 hours of flying, I can’t take it any more! What’s more, it’s responsive, comfortable and, even without turbo, you can climb very quickly. It’s a real pleasure! It’s been a great help on our long trips. I’d also like to congratulate Éric on setting up a responsive and efficient customer service at SE Aviation Aircraft. It makes all the difference!

What’s new with SE AVIATION AIRCRAFT?

New machines to optimise our productivity

Two new recruits have joined SE AVIATION AIRCRAFT at our Pontarlier headquarters. They’re not human, though, as they’re a modular lathe with an inclined bed and a milling machine! These two acquisitions now enable us to automate the production of mechanical parts in-house. In short, we’re saving time and money!

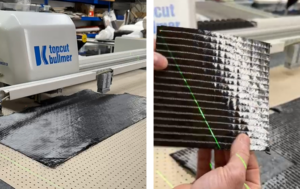

At the same time, a new automatic fabric cutting machine for carbon parts has also been delivered to our Portuguese subsidiary On Air Composite.

With these three new ‘colleagues’, our production rate is set to accelerate.